Product Description

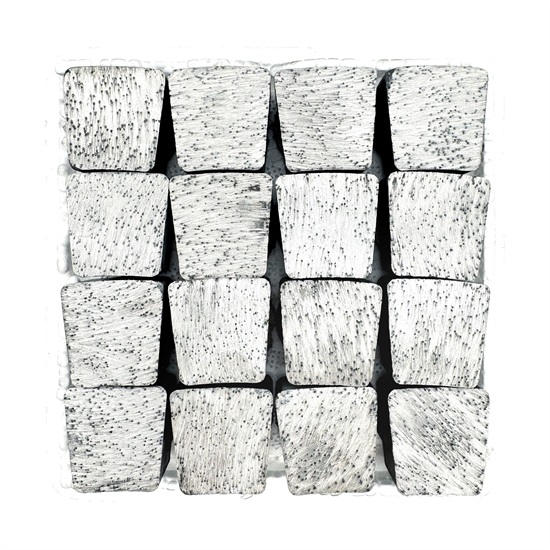

This series of diamond grinding blocks are specially designed for concrete floor grinding, using high-quality diamond particles and scientifically formulated metal bonding agent, with excellent sharpness and abrasion resistance, can quickly and effectively remove the coating, unevenness and impurities of the surface layer of the floor, to achieve the ground leveling grinding and rough and fine polishing. The grinding block has reasonable structural design, convenient loading and unloading, and is suitable for various brands of floor grinders, suitable for all kinds of industrial floors, garage floors, commercial space renovation and treatment work. Different particle sizes can meet the needs of different stages of sanding, which is an indispensable and efficient tool in the construction of flooring.

Product Features

Super abrasion resistance

Wide adaptability

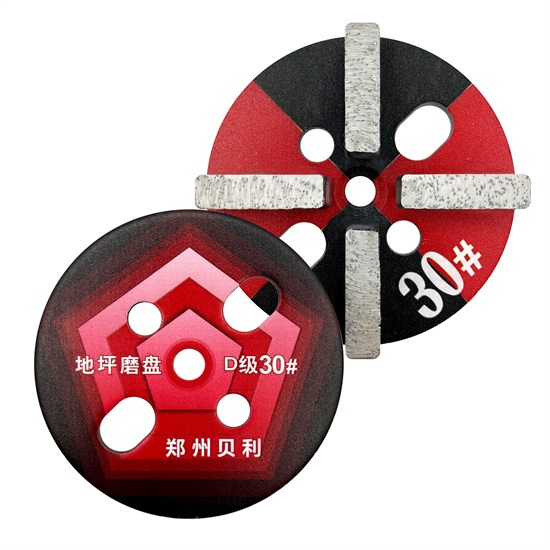

Technical Parameter

| Grade | Diameter | Thickness | Grit | Abrasion Resistance Coefficient | Sharpness Coeffcient | |

| General | 25/20 | 12 | 30/50 | 100 | 100 | |

| Mortar | 12/14 | 30/50 | 50 | 200/248 | ||

| Efficiency | 14 | 30/40 | 125 | 160 | ||

| Sharpness | 14 | 30/40 | 160 | 100 | ||

| Excellence | 15 | 25/30 | 180 | 160 | ||

| Special formulas | Type 1 | 14 | 30/50 | 125 | 100 | |

| Type 2 | 14 | 30/40 | 200 | 100 | ||

| Type 3 | 14 | 30/40 | 140 | 140 | ||

Product Use Recommendations

In order to ensure that the floor grinding disk is used to best effect and to extend its service life, please follow the recommendations below:

Installation and Preparation

- Check equipment match: Make sure the abrasive disc matches the specifications, power and speed of the sanding equipment.

- Install the abrasive disc: Install the abrasive disc to the equipment, make sure the disc is firmly fixed and not loose.

- Check the function of the equipment: After installation, check whether the function of the grinding machine is normal, and make sure the functions of the equipment are running smoothly.

Recommendations for operation during use

- Apply even pressure: Avoid applying excessive pressure during operation and allow the disc to naturally contact the ground. Applying even pressure can improve the cutting effect of the grinding disk and prolong its service life.

- Control of working speed: Avoid advancing too fast and try to maintain a smooth moving speed, which will help to achieve an even grinding effect.

- Wet grinding vs. dry grinding: Choose the appropriate grinding method according to the floor material used. Wet grinding is suitable for reducing dust and improving disc life, while dry grinding is suitable for some special work requirements.

Suggested use scenarios

- Ground cleaning and grinding: suitable for surface treatment of cement floor, millstone floor, epoxy floor, mortar floor, etc.

- Ground polishing: For surfaces that have already been treated, you can use a finer grain abrasive disc to polish and obtain a smooth surface.

- Coating Removal: For old coatings or paints, you can use coarse grain abrasive discs to remove them.

Care and Maintenance

- Regular inspection of discs: After each use, check the wear of the discs. If the disc is badly worn, replace it promptly.

- Cleaning the disc: After use, clean the surface of the disc in time to remove the dust and impurities attached to keep the disc in the best working condition.

- Storage: Avoid exposing the abrasive disc to humid environment, it is recommended to store it in a dry and ventilated place to avoid high temperature and humidity causing damage to the abrasive disc material.

Precautions

- Appropriate operating speed: Ensure that the grinding disc speed and working pressure are in the recommended range during operation to avoid damage to the grinding disc or equipment failure due to overloading.

- Regular inspection of equipment: Ensure that the cables, motors and other components of the equipment are in good condition to avoid operational problems caused by equipment failure.

- Safety protection: Wear safety equipment such as dust masks, ear muffs, gloves, etc. when operating to ensure a safe working environment.

By following these usage recommendations, you can not only improve the working efficiency of your floor grinding disk, but also significantly extend its service life. If you have any questions, please feel free to contact our customer service team, we will provide you with professional technical support.