Selecting the correct saw blade and cutting speed for a road cutter is critical to achieving clean cuts, extending equipment life, and ensuring work efficiency. Below is a detailed, step-by-step guide tailored to practical construction scenarios:

1. Key Principles for Saw Blade Selection

Saw blades must match the pavement material (the core factor) and the road cutter’s specifications. Here’s how to choose:

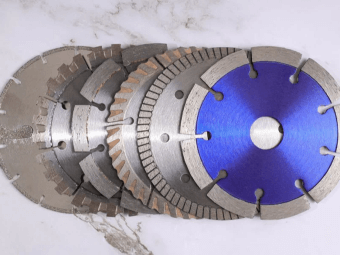

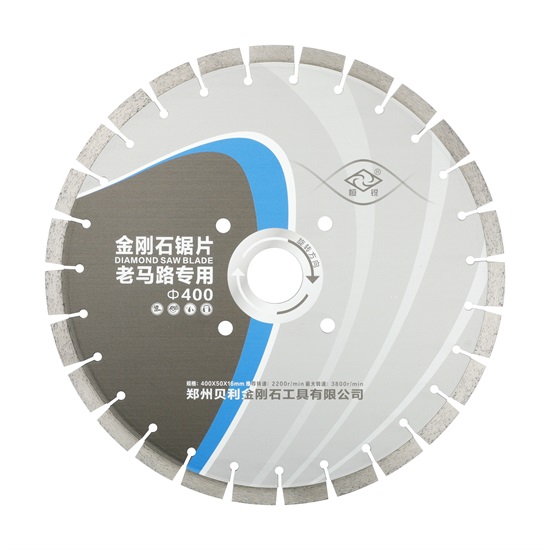

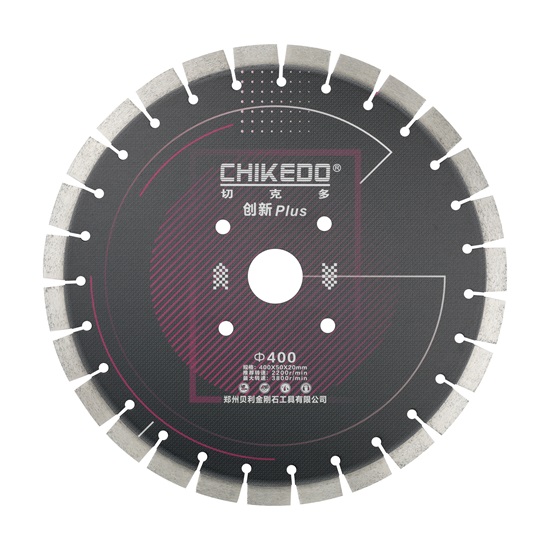

- Concrete (reinforced or plain): Opt for diamond segmented saw blades. For plain concrete (no steel reinforcement), use blades with larger diamond segments (8–12mm) and a softer bond matrix—this allows diamonds to expose quickly for fast cutting. For reinforced concrete, select blades with smaller, denser segments (5–8mm) and a harder bond matrix to resist wear from steel bars.

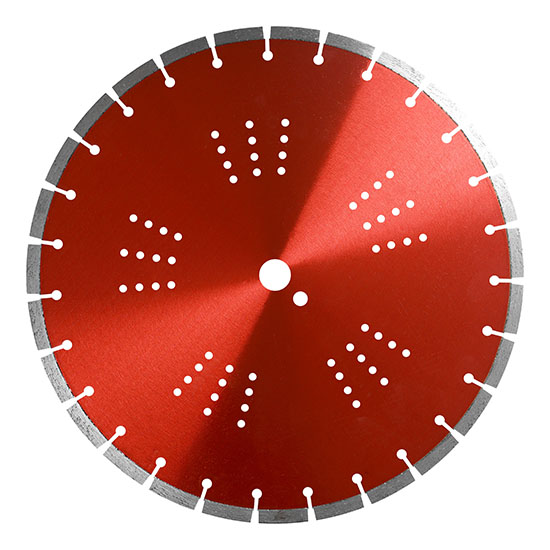

- Asphalt or bituminous pavement: Choose diamond turbo blades or carbide-tipped blades. Turbo blades have curved segments that reduce friction and prevent asphalt from sticking to the blade; carbide-tipped blades are cost-effective for light-duty asphalt cutting. Avoid dense diamond segmented blades—they may cause asphalt to tear rather than cut cleanly.

- Brick, block, or pavers: Use continuous-rim diamond blades for smooth, chip-free cuts. These blades have a solid rim with embedded diamonds, ideal for brittle materials that crack easily.

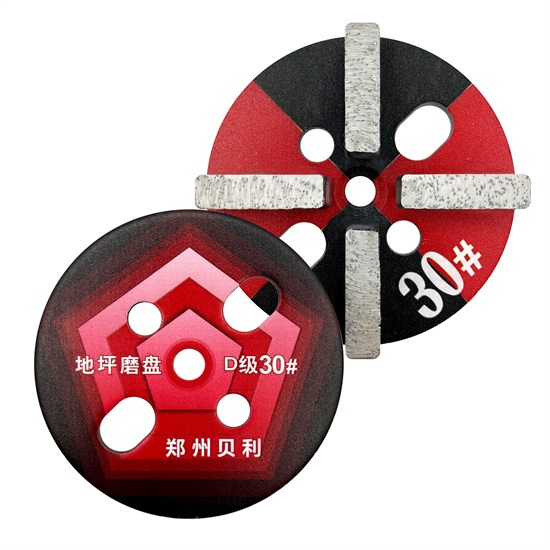

- Cutter compatibility: Ensure the blade’s arbor size (the central hole diameter) matches the road cutter’s spindle. Common sizes are 20mm, 25.4mm (1 inch), and 30mm—check the cutter’s manual to avoid mismatches.

2. Guidelines for Setting Cutting Speed

Cutting speed (often referred to as blade peripheral speed, measured in m/s or ft/min) depends on the pavement material, blade type, and cutter power. Follow these rules:

- Concrete:

- Plain concrete: Run the blade at a peripheral speed of 30–40 m/s (98–131 ft/min). Higher speeds optimize cutting efficiency without overheating the blade.

- Reinforced concrete: Reduce speed to 25–35 m/s (82–115 ft/min). Lower speeds minimize blade wear when cutting through steel and prevent segment damage.

- Asphalt: Use a higher speed of 35–45 m/s (115–148 ft/min). Asphalt is softer, so faster speeds create smoother cuts and avoid material buildup on the blade.

- Brick/pavers: Keep speed moderate at 28–33 m/s (92–108 ft/min). Excessively high speeds can cause brittle materials to chip, while low speeds lead to uneven cuts.

- Adjust for blade diameter: Larger blades (e.g., 300–500mm) require slightly lower speeds to maintain safe peripheral velocity—refer to the cutter’s manual for diameter-specific speed ranges.

3. Practical Tips for Optimization

- Test before full-scale cutting: Make a 5–10cm test cut to check for issues. If the blade vibrates excessively, the speed is too high or the blade is mismatched; if cutting feels labored, reduce speed or switch to a blade with a softer bond.

- Monitor blade temperature: If the blade becomes discolored (blue or black) or emits smoke, slow down—overheating damages the diamond segments or carbide tips.

- Consider cut depth: For deep cuts (over 10cm), use slower speeds and make multiple passes. This reduces blade stress and ensures straight, clean results.

- Follow manufacturer recommendations: Always check the road cutter and blade manuals—they provide material-specific speed and blade type guidelines tailored to the equipment’s design.

4. Common Mistakes to Avoid

Setting speed too high: Causes blade vibration, overheating, and potential segment loss—posing safety risks.

Using a concrete blade for asphalt (causes tearing and blade clogging) or vice versa (leads to rapid wear).

Setting speed too low: Results in inefficient cutting, increased blade wear, and uneven edges.