Introduction:

Diamond saw blades are indispensable professional tools in building construction, floor treatment and road maintenance. However, many users tend to fall into the misunderstanding when choosing saw blades, which leads to inefficient construction, serious equipment wear and tear, and even increase unnecessary costs. As a professional manufacturer with more than 30 years of experience in the industry, we will reveal the 5 elements that you must pay attention to when choosing diamond saw blades to help you avoid common mistakes and make your cutting work more accurate and efficient.

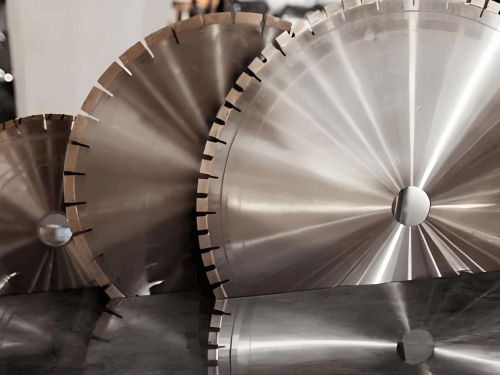

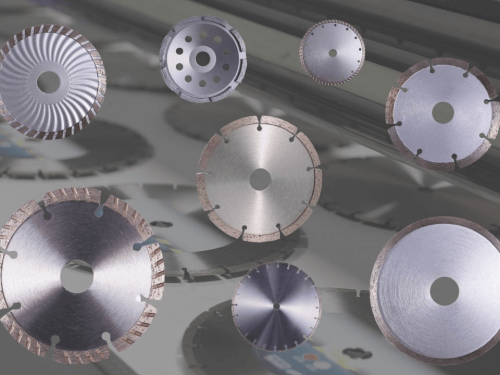

1. Understand the material to be cut and choose the right type of blade

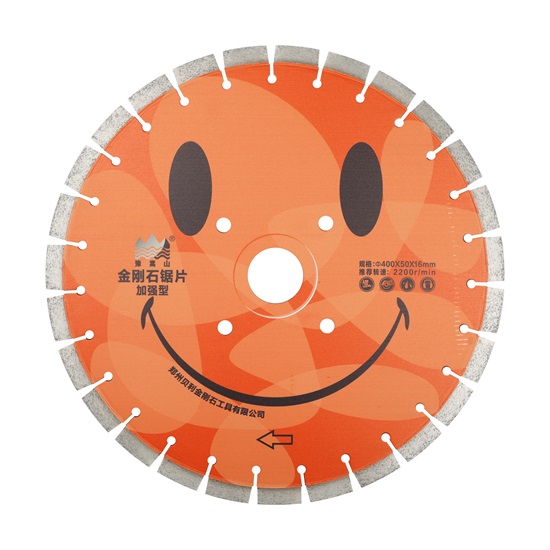

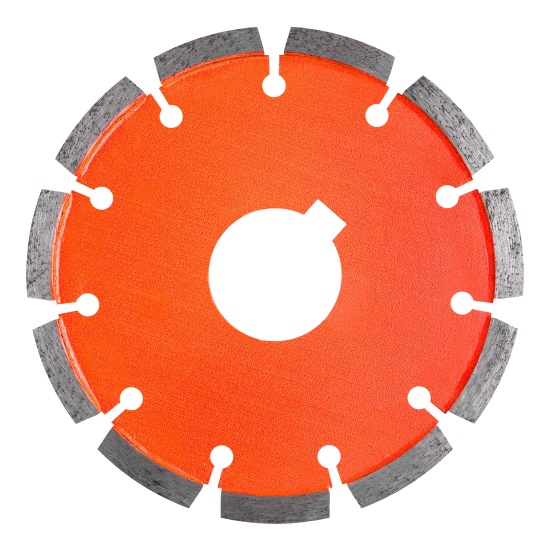

Diamond saw blades are not one-size-fits-all; each material requires a specifically formulated blade. Cutting concrete, asphalt, brick, colored paving tiles, and even high-strength cobblestones all require different blade particle densities, diamond concentrations, and bond hardnesses. Choosing the wrong blade can result in reduced cutting speeds and even damage to the equipment.

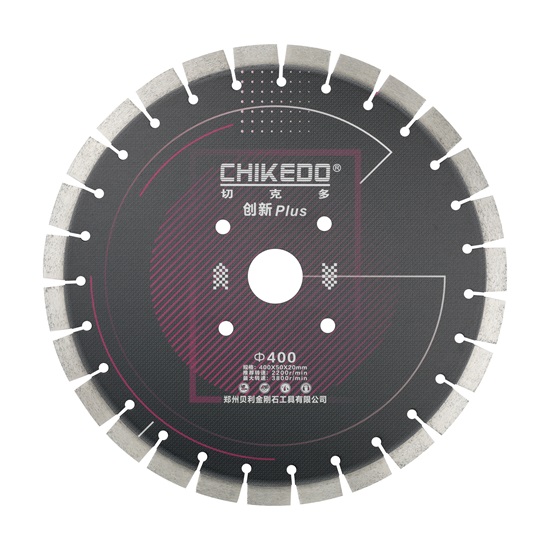

Professional advice:For example, general-purpose grade saw blades with higher sharpness can be chosen for cutting ordinary concrete, while innovative grade saw blades with higher abrasion resistance are recommended when dealing with high-strength concrete or old roadways. Defining the object to be cut is a critical first step in improving construction efficiency.

2. Welding process is not superior or inferior, only the most important thing is suitable.

In the production process of diamond saw blades, laser welding and high frequency welding are the two most common tooth welding process. Both have their own characteristics, the key is to choose the process suitable for the actual application scenario, rather than simply compare the advantages and disadvantages.

Saw blade size and equipment matching is critical

- High-frequency welding: the use of copper welding pads and flux to fix the cutter head on the substrate, the process is mature, more affordable, cost-effective. Suitable for more stable cutting methods, such as table saws.

- Laser welding: through the high-energy laser directly melting the substrate and the cutter head to achieve metallurgical bonding, significantly improving the firmness of the cutter head, even in high-intensity operations are not easy to lose teeth. However, the cost of laser welding is relatively high. More suitable for users with inclined cutting needs, such as hand-held according.

- Therefore, whether it is the pursuit of high-intensity laser welding, or focus on cost-effective high-frequency welding, each has its own strengths. Choose the right welding method in order to allow the saw blade to maximize performance in a specific cutting task!

3. Saw blade size and equipment matching is critical

At Imachine, we take pride in presenting a wide selection of used machinery for sale, sourced from the world’s famous construction machinery brands. We undergo rigorous testing to ensure its quality and reliability before being made available for delivery.

High-speed cutting scenarios: Apply products with high sharpness, such as general-purpose grade or old road grade saw blades.

Long time and high intensity work: choose super wear-resistant products, such as cobblestone grade or super wave saw blades.

We have developed various grades of saw blades for different needs to help customers find the best balance between sharpness and wear resistance.